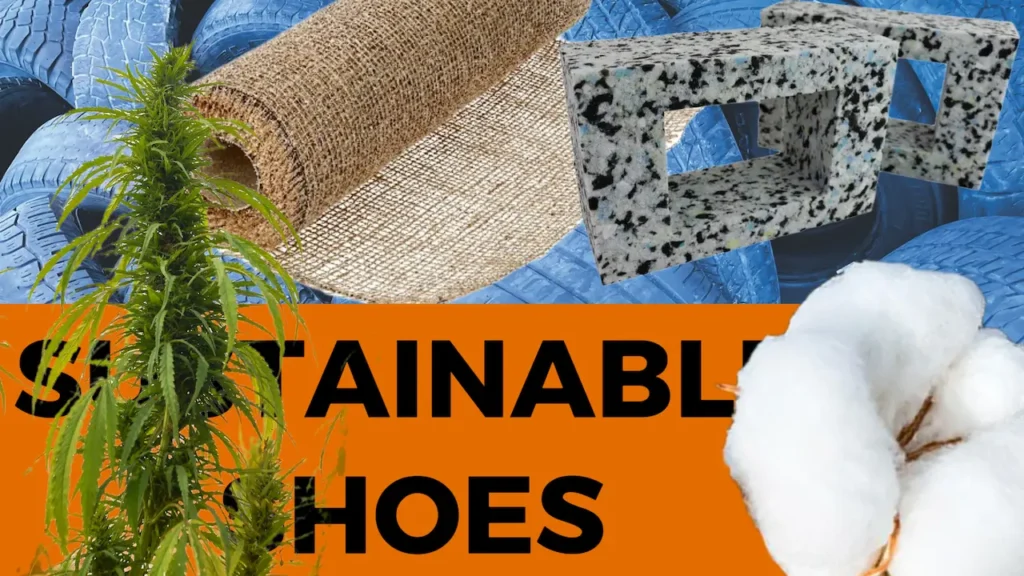

In recent years, the footwear industry has faced increasing scrutiny for its environmental impact. Traditional shoe manufacturing relies on synthetic materials derived from plastic and rubber, which contribute to pollution. In response, sustainable materials create shoes that are kinder to the planet.

This shift has led to innovative solutions and a growing demand for sustainable footwear. But what exactly are these materials, and how do they make shoes environmentally friendly?

Natural Fibers: Harnessing Nature’s Resources

Natural fibers are biodegradable. They require fewer resources to produce compared to synthetic alternatives. By incorporating natural fibers into footwear design, manufacturers significantly reduce their reliance on petroleum-based materials.

Organic Cotton

Cotton has long been a staple material in the textile industry. But conventional cotton farming is notorious for its heavy use of pesticides, fertilizers, and vast amounts of water.

Organic cotton, on the other hand, is grown without these harmful chemicals. This eco-friendly cotton is increasingly being used in the uppers of sneakers.

The benefits of organic cotton extend beyond its chemical-free cultivation. Organic farming practices promote soil health by encouraging biodiversity and using crop rotation techniques.

This not only reduces erosion but also enhances the fertility of the land over time. Additionally, organic cotton farms typically require less water than conventional cotton fields due to improved soil retention and irrigation methods.

By choosing shoes made from organic cotton, consumers contribute to reducing the overall ecological footprint of the fashion industry.

Hemp

Hemp is another natural fiber that has gained significant traction in the world of footwear. Known for its resistance to mold and mildew, hemp is an excellent choice for crafting durable and comfortable shoes.

One of the standout features of hemp is its minimal environmental impact. It requires far less water than cotton and thrives without the need for chemical pesticides.

Beyond its low resource requirements, hemp plants play a crucial role in combating climate change. During their growth cycle, hemp plants absorb large amounts of carbon dioxide (CO2) from the atmosphere.

In fact, hemp absorbs more CO2 per hectare than trees. It is one of the most efficient crops for sequestering greenhouse gases. Shoes made from hemp also align with broader efforts to mitigate global warming.

Hemp’s versatility extends to its application in various parts of the shoe. It is used in uppers, linings, and structural components. Its strength and flexibility make it suitable for a wide range of footwear styles.

Jute and Sisal

Jute and sisal have found their way into sustainable shoe design. Both jute and sisal are lightweight, and fully biodegradable. Jute, referred to as the golden fiber, is derived from the stems of the jute plant, while sisal comes from the leaves of the agave plant.

These materials are commonly used in the construction of eco-friendly sandals, espadrilles, and summer footwear. Their natural texture adds a rustic charm to the final product. Jute and sisal are particularly well-suited for crafting soles.

Moreover, the cultivation of jute and sisal is highly sustainable. These plants grow quickly, require minimal water, and thrive in poor soil conditions. By incorporating jute and sisal into footwear, you can support rural economies and promote sustainable farming practices.

Wool

Wool is a renewable resource that has been used in footwear for centuries. Sourced primarily from sheep, wool is prized for its insulating properties, and natural odor resistance. These qualities make it an exceptional material for cold-weather boots, slippers, and hiking shoes.

What sets wool apart from synthetic materials is its ability to regulate temperature. Wool fibers trap heat in cooler environments while allowing excess moisture to escape. This makes wool an ideal choice for winter footwear.

Recycled Materials: Giving Waste a Second Life

Another cornerstone of sustainable shoe design lies in the innovative use of recycled materials. Recycled materials help conserve natural resources and address the growing issue of waste management. Here’s how some of these materials are transforming the footwear industry.

Recycled Polyester (rPET)

The process of creating rPET involves collecting and cleaning plastic waste, shredding it into flakes, melting it down, and spinning it into new fibers. These fibers are then woven into fabrics used in shoe uppers, linings, and laces. The result is a material that retains all the performance characteristics of traditional polyester.

Many athletic shoe brands have embraced rPET. Running shoes made with recycled polyester uppers perform well during workouts. By choosing shoes made with rPET, you can actively participate in the circular economy, where waste is transformed into valuable products.

Recycled Rubber

Rubber is a critical component of shoe soles. However, the production of traditional rubber is resource-intensive. Recycled rubber offers a greener alternative by sourcing material from discarded tires, industrial scraps, and post-consumer waste.

The recycling process involves grinding old rubber products into small particles, which are then melted and molded into new soles. Recycled rubber retains the same functional properties as conventional rubber.

Recycled rubber is particularly popular in the production of casual shoes, sneakers, and outdoor footwear. Its rugged texture and resilience make it ideal for creating durable soles. By opting for shoes with recycled rubber soles, you can help divert millions of tons of rubber waste from landfills each year.

Recycled Foam

Foam is a key material in the midsoles of shoes. They provide cushioning and support for optimal comfort. Sustainable shoes are made of recycled foam, which is created by reprocessing old foam materials or blending them with bio-based ingredients.

The process of creating recycled foam involves collecting discarded foam products, breaking them down into smaller pieces, and reforming them into new midsoles.

This approach reduces the need for virgin foams. Some brands go a step further by incorporating plant-based oils or algae biomass into the foam formulation.

Bio-Based Materials in Sustainable Shoes

The development of bio-based materials represents a cutting-edge frontier in sustainable footwear. These materials mimic the properties of traditional synthetics. By harnessing the power of nature, bio-based materials reduce environmental harm and introduce groundbreaking innovations that push the boundaries of sustainable design.

Plant-Based Leathers

Plant-based leathers have emerged as innovative substitutes. It mimics the texture and appearance of real leather.

Piñatex is a popular plant-based leather used in sustainable footwear. The fibers are a byproduct of pineapple farming. No additional land or resources are required for its production. This material is lightweight, durable, and versatile.

Derived from apple waste generated by the fruit juice industry, this material transforms discarded peels into a soft fabric. Apple peel leather is eco-friendly and offers a unique texture and finish.

Mushroom mycelium is another exciting innovation in sustainable footwear. By growing fungal networks on agricultural waste, manufacturers can produce a leather-like material that is biodegradable and highly customizable.

Mycelium leather is breathable, strong, and has a luxurious feel. It is an ideal choice for high-end shoes.

Cork is harvested from the bark of cork oak trees without harming the tree itself. This renewable resource is naturally water-resistant, and antimicrobial. Cork leather is increasingly being used in sandals, flats, and casual shoes.

These plant-based leathers address the environmental and ethical concerns associated with traditional leather and offer unique aesthetic and functional qualities that appeal to modern consumers.

Algae Foam

Algae foam is a groundbreaking material that is being used in some eco-friendly shoe soles. This innovative foam is made from harvested algae biomass, which helps combat aquatic overgrowth caused by nutrient pollution in lakes and rivers.

Excessive algae blooms deplete oxygen levels in water bodies. These dead zones threaten marine life. By harvesting algae for use in footwear, brands can help restore balance to aquatic ecosystems while creating sustainable products.

Algae foam provides cushioning comparable to traditional EVA foam. It is lightweight, and durable. It is widely used in athletic shoes, sneakers, and casual footwear.

Corn-Based Plastics

Polylactic acid (PLA), a type of bioplastic derived from fermented corn starch, is increasingly being used in sustainable shoe components. PLA is a renewable and compostable material that serves as a viable alternative to conventional plastics.

Unlike petroleum-based plastics, PLA breaks down under industrial composting conditions within months.

PLA is commonly used in the production of shoe uppers, laces, and structural elements. Its versatility and ability to mimic the properties of traditional plastics make it an attractive option. Additionally, PLA production generates fewer greenhouse gas emissions compared to traditional plastic manufacturing.

Upcycled and Deadstock Materials to Reduce Fashion Waste

Sustainable shoes are using upcycling and utilizing deadstock materials to minimize waste. These approaches reduce the environmental impact of shoe production.

Upcycled Fabrics

Upcycling involves transforming discarded textiles. This method transform old denim jeans, surplus military canvas, and vintage fabrics into new shoe designs. This process prevents valuable materials from ending up in landfills.

Upcycled shoes feature bold patterns, textures, and colors that reflect the original fabric’s history. These shoes are stand out in a market saturated with mass-produced goods.

Deadstock Leather

Deadstock leather refers to leftover hides from luxury goods production that would otherwise go unused. By repurposing deadstock leather, the valuable resources aren’t wasted. This approach reduces waste and aligns with ethical practices by maximizing the utility of existing materials.

Deadstock leather is used in premium footwear, including dress shoes, loafers, and handcrafted boots. Its high-quality finish and durability make it indistinguishable from newly sourced leather.

Biodegradable and Compostable Shoes

These products break down naturally at the end of their lifecycle, leaving behind little to no environmental impact. This closed-loop approach ensures that shoes return to the earth as nutrients rather than lingering in landfills for centuries.

Biodegradable Soles

Traditional rubber and synthetic soles take hundreds of years to decompose. They release harmful microplastics into the environment during the process. In response, biodegradable soles are made from natural rubber, plant-based compounds, and food waste.

Sourced from rubber trees, natural rubber is biodegradable and offers excellent grip and flexibility. Theses soles decompose quickly under the right conditions.

Some soles are made from food waste, such as potato starch or orange peels. These materials provide structure and durability while breaking down naturally after disposal.

When disposed of properly, biodegradable soles decompose within months rather than centuries.

Compostable Footwear

Compostable shoes are made entirely from materials like organic cotton, natural latex, jute, and biodegradable glues. Once the shoes reach the end of their usable life, they can be placed in a compost bin, where they will naturally degrade and return to the earth as nutrient-rich soil.

Some minimalist sneakers with removable insoles and laces allow customers to easily separate components for composting. Single-material shoes simplify the decomposition process. By choosing compostable footwear, you can actively participate in a circular economy.

The range of eco-friendly materials available today is vast and inspiring. Each step taken in sustainable shoes contributes to a larger movement toward a cleaner planet.